The Chemical Engineering Institute went to Yichang to carry out the 90% 3D model review work for the Hubei Yihua insurance powder project.

Release time:

2024-12-25 16:57

Source:

Chemical Engineering and Pharmacy Institute

Responsibility:

Feng Jin

On December 24, the chemical institute held a successful review meeting for the 90% three-dimensional model of the sulfur residue comprehensive utilization project with an annual output of 80,000 tons of insurance powder designed by Hubei Yihua Fine Chemical Co., Ltd.

The director of the construction institute and project manager Li Zhenhua, along with Kong Xiaoming, led the project team members to participate in this review meeting.

This project is for the comprehensive utilization of sulfur residue with an annual output of 80,000 tons of insurance powder. The total area of the project is about 240 acres, and the construction scale includes a production line for insurance powder with an annual capacity of 80,000 tons, supporting production lines for sodium metabisulfite at 40,000 tons/year and liquid sulfur dioxide at 60,000 tons/year, as well as supporting utilities.

This project is for the comprehensive utilization of sulfur residue with an annual output of 80,000 tons of insurance powder. The total area of the project is about 240 acres, and the construction scale includes a production line for insurance powder with an annual capacity of 80,000 tons, supporting production lines for sodium metabisulfite at 40,000 tons/year and liquid sulfur dioxide at 60,000 tons/year, as well as supporting utilities.

The 90% model review covered four sections: sodium metabisulfite section, insurance powder section, post-treatment section, and public auxiliary section, as well as external pipe corridors. The review was conducted in the order of raw material warehouse → synthesis workshop → drying workshop → transfer tank area → sulfur residue workshop → sodium metabisulfite workshop → insurance powder packaging workshop → insurance powder tank area → public gas tank → post-treatment workshop → freezing station → waste liquid tank area. During the review process, the main process personnel detailed the design aspects of each building and equipment model to ensure that every part meets production requirements while firmly maintaining safety production standards. Additionally, the three-dimensional piping personnel provided detailed introductions and explanations for each designed pipeline in accordance with the process flow diagram and engaged in in-depth discussions and communications with owners and technical parties. All responsible parties explored optimal solutions through detailed communication to ensure the rationality of project design and feasibility for later operations.

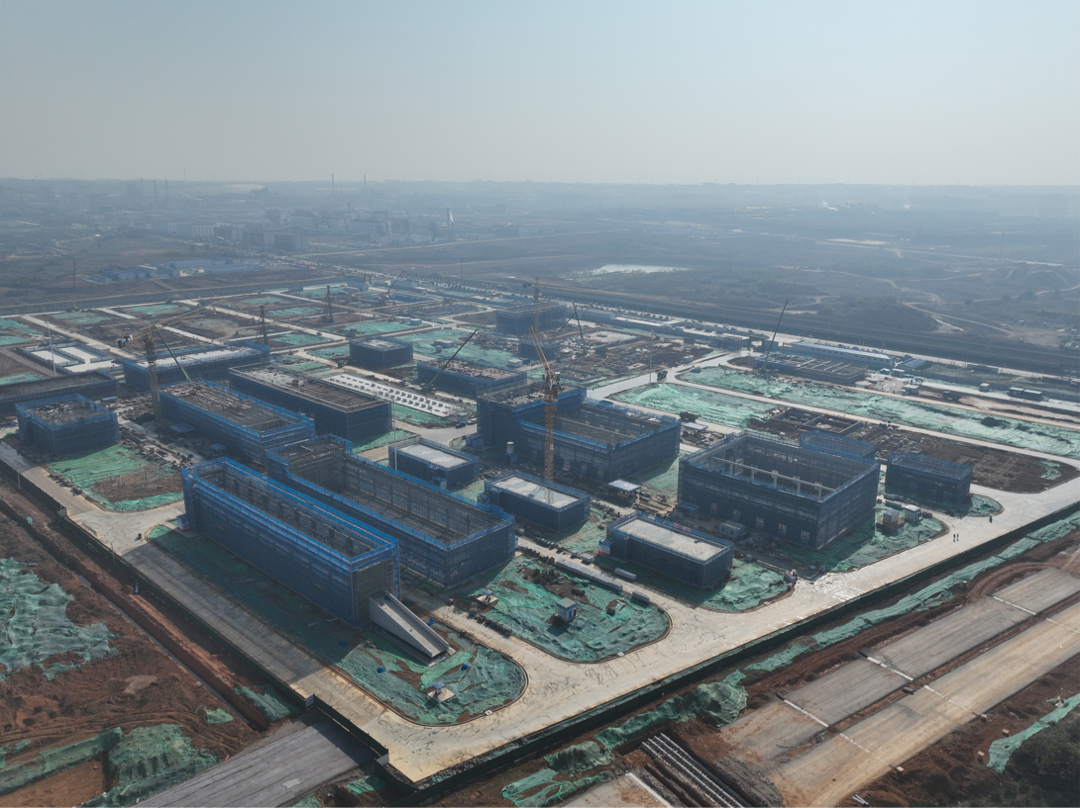

This 90% three-dimensional model review not only marks significant progress in project design work but also indicates another technological innovation and capacity enhancement for Hubei Yihua Group in the field of insurance powder production. At the same time, it lays a solid foundation for subsequent construction. Currently, on-site construction is progressing smoothly, with most individual main structures expected to be capped by the end of December.

It is reported that Hubei Yihua Group Co., Ltd. originated from a chemical plant established in Yichang in 1977 and is a key state-owned enterprise under Yichang City, known as the 'eldest son of Yichang industry,' currently employing over 20,000 people. Yihua Group has more than 30 production subsidiaries in Hubei, Xinjiang, Inner Mongolia, Qinghai, etc., and holds a listed company Hubei Yihua. It possesses mineral resources such as coal mines, phosphate mines, and salt mines with reserves of 2.7 billion tons and an annual mining capacity of 40 million tons. It currently has 25 leading products including: phosphate compound fertilizer (2.3 million tons), urea (2.2 million tons), polyvinyl chloride resin (1.14 million tons), caustic soda (810,000 tons), melamine (80,000 tons), insurance powder (80,000 tons), pentaerythritol (60,000 tons), biodegradable materials (60,000 tons), trimethylolpropane (20,000 tons). Its fertilizer production capacity ranks third in the country; polyvinyl chloride production capacity ranks fifth; pentaerythritol production capacity ranks second globally and first in Asia; its products enjoy a good reputation in both domestic and international markets and are sold in multiple countries and regions including India, Pakistan, Russia, and Southeast Asia.

As a provincial-level chemical design institute and a provincial specialized enterprise recognized for its innovation in education-industry integration 'graduate joint training base,' the chemical institute has strong technical strength and heritage. Its related technologies are 'specialized' with distinct characteristics and obvious advantages. It has three technical innovation platforms: 'Provincial Enterprise Technology Center' recognized by Hunan Provincial Department of Industry and Information Technology; 'Municipal Electrochemical Energy Storage Material Technology Innovation Center' recognized by Changsha Science and Technology Bureau; 'Municipal Enterprise Technology Center' recognized by Changsha Development and Reform Commission. In chemical project design processes, the chemical institute adheres to 'safety design as the primary task; green design as core concept; innovative design as core competitiveness; intelligent design as development direction,' accumulating rich engineering experience in terms of process reliability, applicability, safety aspects as well as technical rationality, advancement across different process technology routes. Particularly in subcategories like insurance powder and sodium metabisulfite products where it has accumulated numerous mature project achievements; related process technologies for insurance powder and sodium metabisulfite are leading domestically: projects such as China Salt Hongsi's annual output of 150,000 tons insurance powder phase one project with an annual output of 100,000 tons insurance powder project; sodium metabisulfite device; Yueyang Zhongcheng Industrial's annual output of 100,000 tons insurance powder and 6,000 tons bleaching powder project; China Salt Chemical Base's insurance powder project upgrade technical reform engineering design; Ningxia Tianyin Technology's annual output of 600,000 tons sodium metabisulfite and annual output of 80,000 tons insurance powder project.

Latest information

湘公网安备 43011102001763号

湘公网安备 43011102001763号