Meticulously crafted quality projects, the two major electric boiler engineering design projects of the Chemical Engineering Institute have been successfully delivered.

Release time:

2024-12-18 22:24

Source:

Public Equipment Office

Responsibility:

Liu Renjie

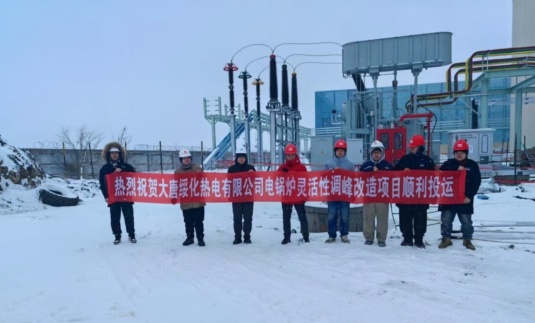

Recently, the flexibility peak-shaving renovation project of the electric boiler undertaken by the Chemical Institute for Datang Suhua Thermal Power Co., Ltd. and the EPC project of the high-pressure electrode steam boiler system for Zouping Hongli Thermal Power Co., Ltd. successfully connected to the grid. After completing the flexibility renovation design project for Datang Linqing Thermal Power Company, the Chemical Institute has added two successful achievements in the field of electric boiler energy storage and peak shaving. The characteristics of electrode boilers include small size, high efficiency and energy saving, rapid startup, low maintenance workload, no pollution, and optimal overall investment. They are applied in various fields such as nuclear power plants, flexible peak shaving, urban heating, and industrial steam, capable of meeting various application requirements based on different usage situations. Both projects are equipped with cutting-edge electric boiler technology; among them, the Heilongjiang Suhua project provides urban heating hot water through a large thermal storage tank for an electrode hot water boiler, while the Shandong Weiqiao project provides superheated steam for centralized heating in a park through an electrode steam boiler. Against the backdrop of vigorous development of new energy sources, high-pressure electrode boilers have shown their advantages as important technical means for peak shaving, energy storage, and reducing carbon emissions with significant economic benefits. The Chemical Institute has leveraged its profound foundation and professional strength in energy engineering to achieve successful operation from design to construction to grid debugging within just four months for both projects, accumulating rich experience in expanding and applying electric boiler technology.

The characteristics of electrode boilers include small size, high efficiency and energy saving, rapid startup, low maintenance workload, no pollution, and optimal overall investment. They are applied in various fields such as nuclear power plants, flexible peak shaving, urban heating, and industrial steam, capable of meeting various application requirements based on different usage situations. Both projects are equipped with cutting-edge electric boiler technology; among them, the Heilongjiang Suhua project provides urban heating hot water through a large thermal storage tank for an electrode hot water boiler, while the Shandong Weiqiao project provides superheated steam for centralized heating in a park through an electrode steam boiler. Against the backdrop of vigorous development of new energy sources, high-pressure electrode boilers have shown their advantages as important technical means for peak shaving, energy storage, and reducing carbon emissions with significant economic benefits. The Chemical Institute has leveraged its profound foundation and professional strength in energy engineering to achieve successful operation from design to construction to grid debugging within just four months for both projects, accumulating rich experience in expanding and applying electric boiler technology. In these two designed electric boiler projects, the Chemical Institute demonstrated superb professional standards and a customer service philosophy. One project is located in Heilongjiang Suhua and the other in Shandong Weiqiao; both are situated in northern regions where winter climates are harsh and environments are relatively severe. Extremely low temperatures posed significant challenges to project construction. To ensure that design plans closely align with actual construction, the design team led by public utilities did not back down; since project initiation, they quickly clarified responsibilities among team members from various specialties and collaborated closely to set precise daily work goals under time pressure. All personnel worked day and night at their posts with a firm belief that they would not leave until their goals were met while making every effort on-site. Especially for the Suhua project, the project leader took charge on-site as a primary representative role while coordinating various needs from owners and construction units. Faced with multiple units working simultaneously on-site under complex conditions with extremely tight schedules and other challenging issues, they overcame each obstacle one by one with tenacity and superb professional skills while steadily advancing project progress to ensure that all key tasks were completed efficiently and effectively—embodying the spirit of craftsmanship.

In these two designed electric boiler projects, the Chemical Institute demonstrated superb professional standards and a customer service philosophy. One project is located in Heilongjiang Suhua and the other in Shandong Weiqiao; both are situated in northern regions where winter climates are harsh and environments are relatively severe. Extremely low temperatures posed significant challenges to project construction. To ensure that design plans closely align with actual construction, the design team led by public utilities did not back down; since project initiation, they quickly clarified responsibilities among team members from various specialties and collaborated closely to set precise daily work goals under time pressure. All personnel worked day and night at their posts with a firm belief that they would not leave until their goals were met while making every effort on-site. Especially for the Suhua project, the project leader took charge on-site as a primary representative role while coordinating various needs from owners and construction units. Faced with multiple units working simultaneously on-site under complex conditions with extremely tight schedules and other challenging issues, they overcame each obstacle one by one with tenacity and superb professional skills while steadily advancing project progress to ensure that all key tasks were completed efficiently and effectively—embodying the spirit of craftsmanship. Throughout the entire project advancement process led by public utilities as pioneers, all departments actively responded and cooperated fully to form a strong synergy. Project leaders and specialists played leading roles by closely monitoring project dynamics while engaging in frequent high-efficiency communication and coordination with clients, manufacturers, general contractors to timely resolve various issues ensuring that all aspects of the project were tightly connected and operated efficiently providing solid guarantees for smooth implementation.

Throughout the entire project advancement process led by public utilities as pioneers, all departments actively responded and cooperated fully to form a strong synergy. Project leaders and specialists played leading roles by closely monitoring project dynamics while engaging in frequent high-efficiency communication and coordination with clients, manufacturers, general contractors to timely resolve various issues ensuring that all aspects of the project were tightly connected and operated efficiently providing solid guarantees for smooth implementation.

The Chemical Institute has always adhered to its philosophy of 'safety design as a primary task; green design as core concept; innovative design as core competitiveness; intelligent design as development direction,' deeply cultivating in waste heat power generation and thermal engineering projects while accumulating rich valuable engineering experience. Now that both Zouping Weiqiao's and Datang Suhua's electric boiler systems have successfully connected to the grid again highlights Chemical Institute's strong technical strength along with powerful innovation capabilities which also lays a solid foundation for undertaking more large-scale designs and general contracting projects while accumulating valuable experience.

Latest information

湘公网安备 43011102001763号

湘公网安备 43011102001763号