Good news: The group standard for “Technical Specifications for Biomass Methanol Production”, to which the School of Chemical Engineering contributed, has been officially released and implemented.

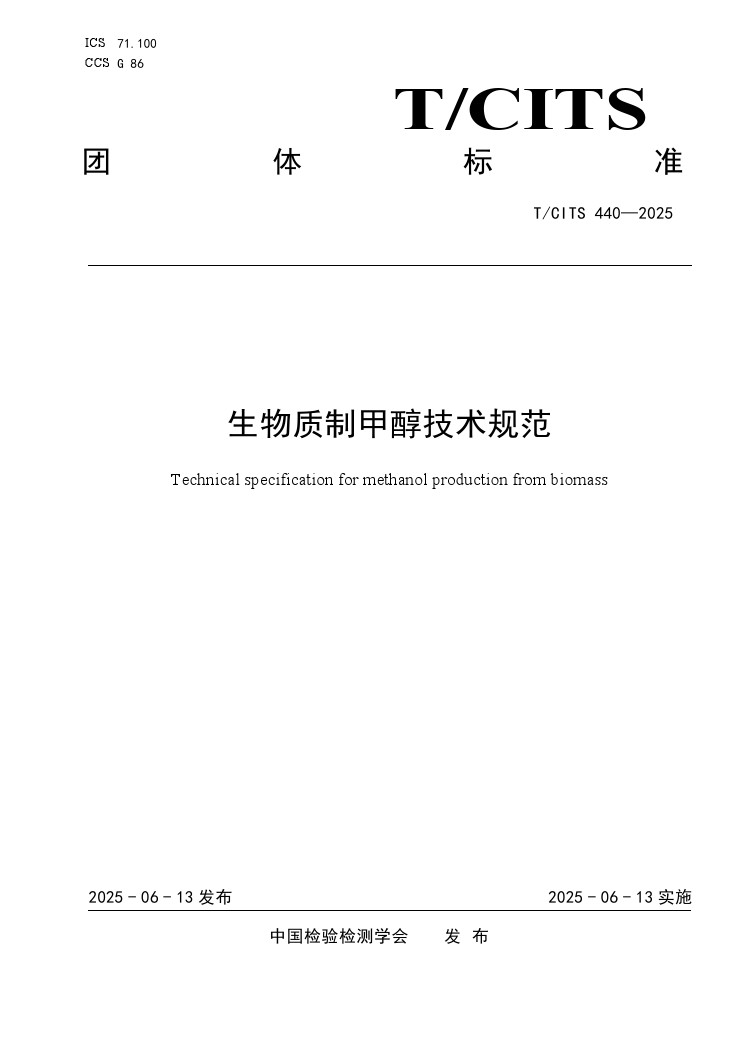

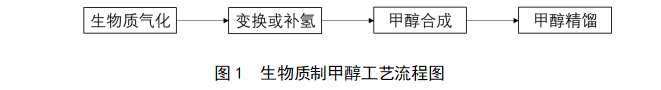

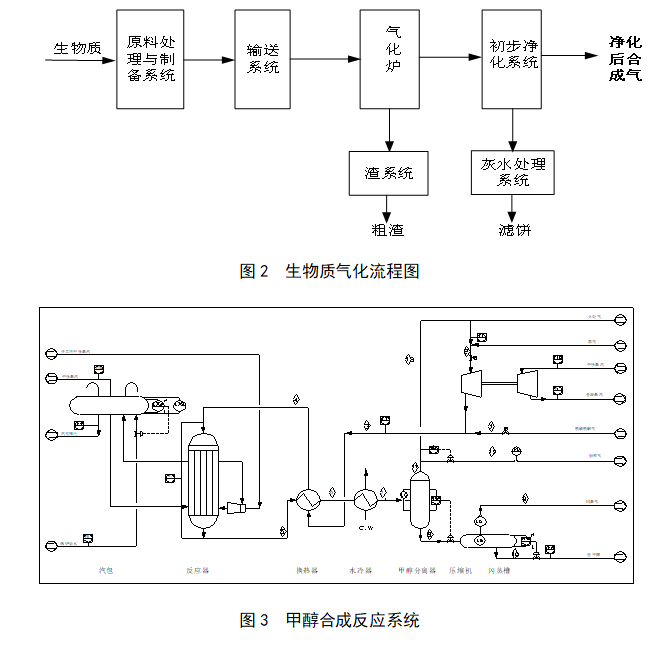

Recently, the Chemical Engineering Institute participated in the development of the group standard "Technical Specification for Methanol Production from Biomass" T/CITS 440-2025, which has been officially released and implemented. This technical specification is the first domestic group standard for methanol production from biomass. It clarifies the technological processes, technical indicators, and safety and environmental protection requirements of gasification, purification, methanol synthesis, and rectification, providing a unified technical specification and guidance for research and design units and production enterprises.

Release time:

2025-07-14 15:11

Source:

Chemical Engineering Branch 1

Responsibility:

Wang Weixian

Recently, the Chemical Engineering Institute participated in the compilation of the "Technical Specification for Methanol Production from Biomass" T/CITS 440-2025 Green Methanol Group Standard, which has been officially released and implemented. This technical specification is the first group standard in China focusing on biomass methanol production technology. It clarifies the process flow, technical indicators, and safety and environmental protection requirements of gasification, purification, methanol synthesis, and rectification, providing a unified technical specification and guidance for research and design units and production enterprises.

China Energy Construction Group Hunan Provincial Power Design Institute and its affiliated Hunan Chemical Engineering Design Institute is the only domestic technical unit with Class A qualifications in both the power and chemical engineering design industries, possessing unique advantages in large-scale new energy bases + green hydrogen, ammonia, and methanol, including advantages in large-base planning, energy chemical technology, and system integration. It has a solid foundation in power capacity optimization configuration theory and application, flexible coordinated optimization configuration of wind, solar, storage, hydrogen, ammonia, and methanol, and rich experience in traditional ammonia and methanol synthesis design. In the field of new energy hydrogen energy industry, integrated electric hydrogen, ammonia, and methanol technology, in recent years, the focus has been on technical breakthroughs in multi-stable green ammonia synthesis, low-temperature and low-pressure flexible green ammonia synthesis, biomass gasification coupled with green hydrogen to produce green methanol, and non-fossil CO2 + green hydrogen to produce methanol. In 2024, the "Construction of a Technical Platform for Integrated Electric Hydrogen, Ammonia, and Methanol Technology in the New Energy Hydrogen Energy Industry," jointly applied for by China Energy Construction Hunan Institute and Chemical Engineering Institute, was successfully included in Hunan Province's 2024 Central Government-guided Local Science and Technology Development Fund projects. This marks a major breakthrough for the green hydrogen, ammonia, and methanol strategy in government scientific research projects, receiving support from the Central Government-guided Local Science and Technology Development Fund.

Green Hydrogen. The Chemical Engineering Institute's research and development in the green hydrogen field began with basic research on water electrolysis technology and gradually expanded to system integration and application technology. Currently, it covers two mainstream technologies: alkaline water electrolysis (ALK) and proton exchange membrane water electrolysis (PEM). It has successfully undertaken and participated in several green hydrogen-related research projects. The research in these projects reflects the Chemical Engineering Institute's professional capabilities in green hydrogen production technology and has enabled the institute to possess strong capabilities in system integration and application development.

Green Ammonia. (1) Multi-stable green ammonia synthesis process direction. Based on traditional ammonia synthesis technology, it has formed its own full-system, multi-stable green ammonia synthesis process package and proprietary technology, and can provide technical services such as project scheme design, feasibility studies, basic design, and detailed design. Participated in the compilation of the "Technical Requirements for Wind-Solar-Hydrogen-Storage-Ammonia-Methanol Integrated Multi-stable Flexible Ammonia Synthesis" green ammonia group standard, which has been officially released and implemented. (2) Low-temperature and low-pressure flexible green ammonia synthesis process direction. The design of reactors, green ammonia processes, and advanced control systems suitable for 10,000-ton-level low-temperature and low-pressure flexible green ammonia has been completed. Based on the completed static simulation calculations, dynamic simulation of the process system and reactor is carried out to verify the compliance, safety, and economy of the synthesis reactor, process scheme, advanced control system, and the entire system, aiming for performance compliance, inherent safety, and optimal cost. Based on the dynamic simulation results, optimized and standardized design will be carried out in subsequent engineering projects.

Green Methanol. (1) In the direction of biomass gasification coupled with green hydrogen to produce green methanol, the operational flexibility of coupling traditional methanol synthesis technology with green hydrogen was demonstrated based on the Shuangyashan project. In the later implementation of the project, its own process package technology and engineering design for biomass gasification coupled with green hydrogen to produce green methanol were formed. Participated in the compilation of the China Inspection and Testing Society's "Technical Specification for Methanol Production from Biomass" group standard, which has been officially released and implemented. (2) In the direction of non-fossil CO 2 + green hydrogen to produce methanol, research and technical exchanges with some catalyst production research units have been completed, and suitable catalyst research institutions can be selected for technical cooperation. It has the ability to integrate process technology routes and catalysts into system design schemes and form its own key technologies.

Especially in the electric-hydrogen-ammonia three-flexible coupling green ammonia integrated technology, based on the characteristics of new energy hydrogen energy large-base projects, highly integrated and coordinated with China Energy Construction Hunan Institute's power system planning, new energy engineering companies, and other departments, from the power system and new energy front-end to the back-end of the hydrogen-ammonia-methanol chemical part, creating a set of three flexible processes (flexible microgrid, flexible hydrogen production, flexible ammonia production) , two types of AI models (electric hydrogen ammonia coordinated flexible interaction system configuration model, optimization control model suitable for three flexible processes) , three typical microgrid schemes (grid-connected type, tie-switch type, independent type) , promoting multiple landing scenarios 。

This technical specification formulates systematic technical specifications around the overall process of biomass methanol production, covering the entire process from biomass gasification → syngas purification → methanol synthesis → rectification and purification, providing necessary technical requirements for engineering design and production operation. The technical specification for biomass methanol production is not only a technical document but also a key tool for achieving energy sustainability, environmental governance, and industrial upgrading.  The Chemical Engineering Institute deeply participated in the formulation and release of this standard, demonstrating its technological leadership and industry influence in the field of biomass methanol and green energy. In the future, the Chemical Engineering Institute will continue to conduct technological research and development in this direction, focusing on breakthroughs in key technologies of biomass methanol production, thereby creating the institute's characteristic technological advantages and innovative productivity.

The Chemical Engineering Institute deeply participated in the formulation and release of this standard, demonstrating its technological leadership and industry influence in the field of biomass methanol and green energy. In the future, the Chemical Engineering Institute will continue to conduct technological research and development in this direction, focusing on breakthroughs in key technologies of biomass methanol production, thereby creating the institute's characteristic technological advantages and innovative productivity.

Latest information

湘公网安备 43011102001763号

湘公网安备 43011102001763号